The electric vehicle (EV) revolution is gaining momentum, with EV batteries manufacturers at the forefront. As the demand for electric vehicles develops, the worldwide spotlight falls on the companies that manufacture these vital power sources.

The market for EV battery manufacturers is predicted to increase from a net worth of $17 billion to $95 billion in a decade. In the last few years, owing to different reasons, the EVs battery industry has become significantly more developed than ever.

In this post, we will look at the top EV battery manufacturers, exploring who is leading the charge in this dynamic industry.

The Importance of EV Batteries

EV batteries are complex systems that have a considerable impact on the performance, cost, and range of electric vehicles. The importance of producing efficient, long-lasting, and low-cost batteries cannot be emphasized, as these features have a direct impact on the global adoption rate of electric cars.

People are taking a keen interest in purchasing EVs worldwide due to the increasing gasoline prices and advancements in EV batteries and technology. The global volume for EVs will expand by 350 million by 2030, and the US alone sets the target of having more than 190 million EVs by this time.

Global Distribution of EV Batteries Manufacturers by Country

| Country | Number of Companies | Share (%) |

|---|---|---|

| United States of America | 3 | 33.3% |

| Republic of Korea | 2 | 22.2% |

| China | 2 | 22.2% |

| Japan | 1 | 11.1% |

| Sweden | 1 | 11.1% |

top EV batteries manufacturers

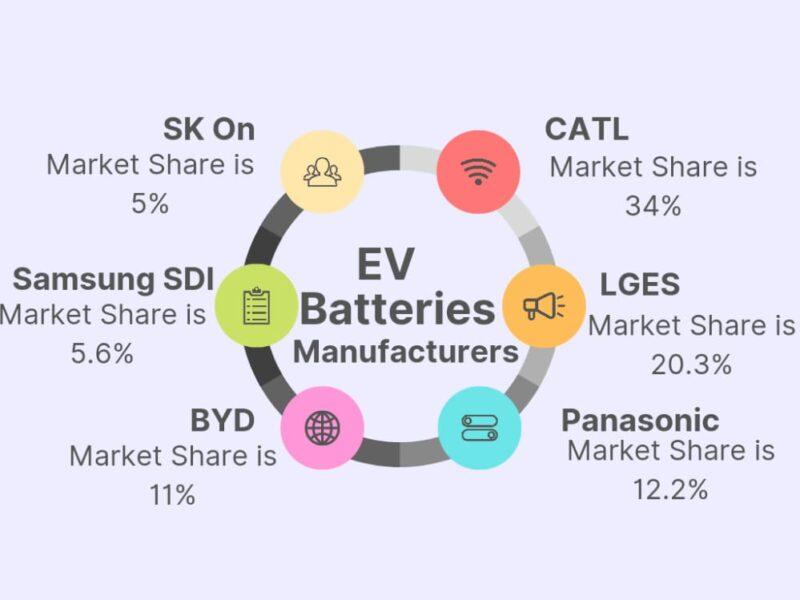

According to reports, EV sales increased twice from 2020 to 2021, reaching 6.6 million. For the first half of 2022, the Chinese manufacturer CATL remained the top seller in the global market for batteries for electric and hybrid cars.

Similar to the previous point, increasing demand has increased the earnings of battery manufacturers and given rise to market competition.

Let us look at a few of them.

- CATL

- LGES

- BYD

- Panasonic

- SK On

- Samsung SDI

Capacity of batteries manufactured in 2022 & 2023

| Manufacturer | 2022 | 2023 |

|---|---|---|

| CATL | 163,831 | 242,300 |

| BYD | 72,841 | 115,917 |

| LGES | 86,575 | 108,487 |

| Panasonic | 45,452 | 56,560 |

| SK On | 31,299 | 40,711 |

| Samsung SDI | 25,262 | 35,703 |

| CALB | 20,125 | 23,493 |

| FARASIS ENERGY | 7,398 | 16527 |

| ENVISION AESC | 4,879 | 8,342 |

| SUNWODA | 4,495 | 6,979 |

| OTHERS | 44,582 | 56,040 |

1- CATL (Contemporary Amperex Technology Company Limited)

It is China’s world’s most reliable battery manufacturing company for EV and hybrid car batteries. It was established in 2011. It is well-known for producing lithium-ion and solid-state batteries for electric cars.

CALT In 2021, for the 5th consecutive year, it has been the largest manufacturer of EV batteries in the market. Contemporary Amperex Technology Co Limited., well known as CATL, has increased its global market share from 2% to 32% in 2021 and 34% in 2022. It expanded significantly after the installation of power battery capacity in 2021, which increased to 96.7 GWh from the recent year.

CATL supplies batteries to major international automakers such as Tesla, BMW, and Volkswagen. The company’s focus on innovation in lithium-ion technology and battery management systems makes it a leader in the field.

Read more:

Do electric cars have catalytic converters? A detailed Guide

2- LG Energy Solution

LG Energy Solution is the second largest manufacturing industry of electric vehicle batteries in South Korea in terms of installed battery capacity with 60.2 GWh.

It is previously called LG Chem, with a 14% share in the global market. In 2021, it had a 20.3% share. It intends to increase its worldwide battery sales by 8% in 2022.

The supplier from South Korea agreed to pay General Motors $1.9 billion in 2021 to cover the cost of 143,000 Chevy Bolt EVs that were recalled due to associated fire risks from defective batteries. It provides battery components to automotive brands such as Porsche, Lucid, and Tesla. It contributes to some of its success in sales. LGES batteries of Tesla Model 3 and Model Y are being sold in China and Europe at a high ratio.

It is a significant stakeholder in Ultium Cells–a joint venture between Energy Solution and General Motors with complete manufacturing in Warren, Ohio. In addition, its factories are currently being built in Lansing, Michigan, Tennessee, and Spring Hill.

3- BYD (Build Your Dreams)

Build Your Dreams has replaced Panasonic in the 3rd position. It is because it has doubled its share in the market from the previous year. Due to the rising demand for batteries in the EV industry, it has started producing batteries in large quantities.

In China, there are 11 factories of BYD, which mostly produce batteries in the range of 200 kWh. From a local news source, it has been found out that BYD will soon start supplying batteries to Tesla. It has been providing batteries to Toyota and other automakers for a long time.

Unlike lithium-ion batteries, which use cobalt or nickel as their main component and are famous for more range, although, at a higher price, BYD has produced a product known as the “Blade Battery.” It is made of lithium-ion phosphate (LEF) and has the qualities of thermal stability and stronger impact resistance.

4- Panasonic

It is a Japanese Multinational Conglomerate company found in Kadoma, Osaka. It provides batteries to hybrid, plug-in, and battery electric vehicles. It has been supplying batteries to US companies. It ranked fourth in terms of installed battery capacity with 36.1 GWh. Its global market share is around 12.2%.

In 2015, it provided batteries to Tesla, with its market share. In 2023, it plans to produce lithium-ion batteries for the world’s top auto manufacturing unit, The Tesla. It is also looking to invest almost $705 million in Japan to produce batteries.

It produced the 4680 format battery ( 80 millimeters long and 46 millimeters wide), and in Western Japan, it will produce 4680 batteries at an industrial plant in Wakayama. It will produce less than 10 GWh of energy annually or around 150,000 automobiles.

5- SK Innovation

It is the 5th biggest EV battery manufacturing company in the world. SK Innovation is with the ambition to make it the largest battery producer for electric vehicles by 2030.

In an interview, Jee said:

we will undoubtedly stand out as the world’s top manufacturer with products that will excel in terms of performance, safety, and affordability.

It is making LFP (lithium-ion phosphate) batteries for EVs. It has a 5.6% battery market share with an installed battery capacity of 17 GWh. It had hit $13.2 billion in sales, reported by South Korea’s SNE Research.

6- Samsung SDI

Samsung SDI, in 2022 lost its fifth rank at the hands of SK Innovation, and now, it is the 6th largest enterprise for manufacturing EV batteries. With 5% of the global market share, It has an installed battery capacity of 23 GWh, and its planning to soon increase it to 33 GWh.

EVP Son Michael, Head of the Automotive & ESS battery Strategic Marketing Team, announced:

that it produces the best quality batteries to give rise to the EV industry.

With the rise in the popularity of electric vehicles, a need to install superior batteries in EVs emerges. We have examined the above six top producers of EV batteries. The market for lithium-ion batteries is still growing at a steady rate. On the contrary, a growing number of companies are found every year.

Challenges Facing EV Battery Manufacturers

Apart from the booming growth, EV battery manufacturers face several challenges:

Supply Chain Issues

EV battery makers rely heavily on certain materials like lithium, cobalt, and nickel to make their products. However, getting these materials isn’t always easy because they are not evenly found all around the world.

This can make the supply chain—the process of getting these materials from their source to the factories that make the batteries—vulnerable. When countries don’t get along or there are trade disagreements, it can make these issues even worse, affecting how many batteries can be made and how much they cost.

Technological Hurdles

There is constant pressure on battery manufacturers to make their batteries better and better. This means they need to ensure the batteries are safe, can charge quicker, and are cheaper to produce.

Achieving these improvements is challenging and requires ongoing research and development. Making a battery safer, faster to charge, and more affordable takes a lot of work and can be quite difficult.

Related Article:

Types of batteries used in electric vehicles: Let’s dive for the best

Competition and Market Pressure

As the market for electric vehicles grows, more companies are starting to make EV batteries. This increase in the number of manufacturers creates more competition. With more players in the market, companies often find themselves in price wars, where they lower prices to attract more customers, which can reduce their profits.

This tough competition forces battery makers to constantly come up with new ideas and innovations to stay ahead of their rivals and remain profitable.

Conclusion

The electric vehicle (EV) revolution is picking up speed, and EV battery manufacturers are leading the way. These companies are crucial as the demand for electric vehicles rises, fueled by high gas prices and better battery technology. The industry’s value is expected to jump from $17 billion to $95 billion in the next ten years.

However, these manufacturers face challenges, including reliance on materials like lithium, cobalt, and nickel, which can lead to supply issues due to political and trade tensions. They also need to constantly improve their technology, making batteries safer, faster to charge, and cheaper to produce. Despite these challenges, the future looks promising for EV battery manufacturers if they can overcome these obstacles and stay ahead in the competitive market.

Frequently Asked Questions

What is the future outlook for EV battery manufacturers?

The future looks promising for EV battery manufacturers despite the challenges. With the EV market expected to grow significantly, there will be a continued demand for advanced and efficient batteries. Success for these manufacturers will depend on their ability to innovate, scale up production, and navigate complex supply chain and market dynamics.

How are EV battery manufacturers responding to market competition?

To stay competitive, EV battery manufacturers are constantly innovating their products. This includes improving battery life, safety, and charging speed, as well as reducing costs. Some are also expanding their production capacity and entering new markets to meet global demand.

Why is there so much focus on EV battery manufacturers?

As electric vehicles become more popular, the demand for efficient and affordable EV batteries increases. Manufacturers are crucial because they develop and produce these batteries, which are key to the performance and cost of electric vehicles. Their role is pivotal in the transition towards sustainable transportation.

What are the main materials used in EV batteries?

EV batteries primarily use lithium, cobalt, and nickel. These materials are essential for creating the battery cells that power electric vehicles. Their availability and cost can significantly affect battery production.

Imran is an experienced content writer who crafts engaging and informative articles for a variety of industries. With a keen eye for detail and a passion for storytelling, Imran delivers high-quality content that resonates with readers. Whether he’s writing blog posts, social media content, or website copy, Imran is committed to delivering compelling content that drives results.