Since, according to battery manufacturers’ claims, most EV batteries still possess about 70 to 80% of their energy after being thrown out of the EVs, they can be used for many alternative purposes before going through the complex recycling process.

A question often asked is, can electric vehicle batteries be recycled? The answer is yes. Recycling electric car batteries is one of the best ways to reduce the environmental impact of electric vehicles. Learn what recycling entails and how to recycle the battery of an electric vehicle.

Can Electric car Batteries be Recycled

Electric car batteries are made up of metals such as nickel, cobalt, lithium, copper, and manganese. These highly strategic metals are essential for a more sustainable energy source.

The recycling process positively impacts the environment because it prevents the extraction of pure metals, which harms biodiversity and water supplies, and reduces carbon emissions of one metric tonne of CO2 equivalent per metric tonne of recycled batteries.

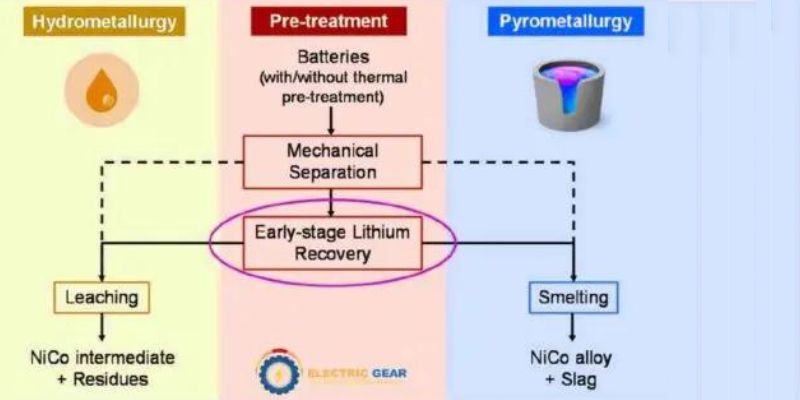

Three Methods of Recycling Lithium-ion Batteries:

1. Pyrometallurgy

2. Hydrometallurgy

3. Direct Recycling

1.Pyrometallurgy

Recycling Li-ion and NiMH batteries involve pyrometallurgy, which is also called smelting. Only 40-50% of the battery’s ingredients are recovered during the resource-intensive process, which releases greenhouse gases. The US Department of Energy states that these precious metals and salts, after refining, are made acceptable for any later usage.

2. Hydrometallurgy

The first step in hydrometallurgy is “separating” the cells to release the metals. It entails employing acids in a solution to dissolve ions.

According to Lithion — a private company that recycles lithium-ion batteries — only 95% of the battery components are recyclable by shredding.

3. Direct Recycling

Argonne National Laboratory states that batteries can be directly recycled after being crushed using techniques like gravity separation that recover functional elements without undergoing chemical changes. EV battery recycling has now started to use these methods, even though they have been there for a while.

According to Spangenberger, “The recycling technology has enormous potential for economic and environmental reasons, but there are a lot of difficulties involved in this process.”

How Will Electric Car Battery Recycling?

Once the electric vehicle battery is out of use, almost 50% of its parts can be recycled.

The question is, “Where do electric car batteries go after they die?” After they stop functioning in the vehicles, they are manufactured again for being in use. Copper, aluminum, plastic, lithium salts, and other essential materials can be extracted from them to reuse them again.

The basic principle is that the battery is rendered inert to avoid mishaps or fires and then crushed, melted, or submerged into acid to extract raw materials. After being cleaned and separated, these parts are resold on the open market to manufacture new batteries.

Manufacturing companies use different techniques for bringing these batteries into use once again. Most companies claim that they recover up to 95% of the raw minerals, including cobalt, nickel, and lithium, from these batteries.

Manufacturers of EVs are working hard to recycle old batteries. Tesla declared that it had begun constructing recycling capabilities at its Nevada Giga factory in August 2021. Redwood Materials, owned by JB Straubel, a co-founder of Tesla, raised $700 million earlier that year to grow its battery recycling business. They intend to establish a “closed loop” supply chain for producing lithium-ion cells using recycled materials. Doing this will eliminate some of the most expensive metals, including cobalt, whose mining in the DRC has had catastrophic effects on the environment and humankind.

Fortunately, battery recycling has started to emerge all over the world. In 2018, the Chinese government unveiled new regulations to encourage the reuse of EV battery components. The EU Commission has suggested a quota for recycling 25% Li-on batteries by 2025, increasing to 70% by 2030.

With the help of the waste management company Veolia and the global chemical giant Solvay, Renault is recycling the batteries for E.V.sE.V.s in Europe. If a lithium-ion battery has stopped working, many parts and raw materials used in its manufacturing are recycled. But its recycling process is complex because the components used in making it are expensive and hard to find.

Challenges of Recycling EV Batteries

Some things could be improved when it comes to recycling electric vehicle batteries. These include:

- Profitability: It’s a big obstacle in the recycling process of batteries. Even though lithium-ion batteries contain rich metals, they are difficult to disassemble, and the minerals are extracted from thick layers of organic and inorganic molecules. According to estimates, recovered lithium costs five times as much as pure lithium from brine mining.

- Lithium-ion battery recycling process is inefficient: Pyrometallurgy is a technique many recyclers use to recover valuable metals by liquefying batteries and burning off the plastic separators. Among other precious minerals, lithium cannot be recovered using pyrometallurgy, which uses a lot of energy and creates harmful pollutants.

Top EV Battery Recycling Companies

Now, we will provide you with a list of five recycling companies for electric car batteries. These are listed below:

1. Li-Cycle: A Canadian company that has now entered the US market. Its main objective is to develop a closed-loop recycling system. It separates various kinds of metal and other items used in electric car batteries for use in lithium-ion-powered items, including cars, phones, etc. Batteries are shredded for the separation and collection of the metals, then dipped into a fire-resistant solution. After that, it restarts the process of producing batteries with these metals.

Li-Cycle asserts that it can recover up to 95% of the battery’s components for recycling.

2. American Battery Technology: A Nevada company that has turned around the process of manufacturing EVEV batteries. Robots created by this company will disassemble these batteries piece by piece of how they were manufactured. It can reassemble the elements for making new lithium-ion batteries by chemically dismantling them into their component cells, then separating them into anodes, cathodes, and separators.

This American company claims to have expedited the process of recycling EV batteries by saving money.

3. Redwood Materials: A recycling company of electric car batteries, developed by co-founder of Tesla, Jb Straubel, uses hydrometallurgy to liquefy the material from dead batteries.

By recovering, reusing, and recirculating raw elements like cobalt, copper, and nickel from broken-down batteries, it also aims to establish a circular or “closed loop” supply chain. Redwood combines pyrometallurgy, which involves burning batteries to eliminate undesired organic and plastic contaminants.

It involves hydrometallurgy and soaking lithium-ion batteries in acids to disestablish the metals into a solution.

4. ReCell: The US Department of Energy is a part of national laboratories, businesses, and academia that aims to advance lithium-ion recycling methods. By recovering high-value materials and devising techniques for maximizing output, productivity, and cost, it intends to make recycling electric car batteries profitable.

It also expects that utilizing science-based techniques to develop affordable recycling of lithium-ion batteries will minimize waste, create jobs, and lessen dependency on foreign raw material suppliers in the U.S.

5. Ascend Elements: A Massachusetts company developed in 2015 uses the ‘Hydro to Cathode’ technique for disassembling batteries. It drains impurities rather than accumulating metals and leaves cathodes in a clean atomic state. These resources help in a closed-loop recycling procedure that remanufactures battery components that can be used in new products, like cell phones.

According to this manufacturing company, it recycles all active battery components up to 100%.

When the batteries of electric vehicles reach the end of their useful lives, automakers attempt to recycle these to recover raw materials that may be used to produce new batteries in the future, making E.V.sE.V.s more sustainable and accessible.

Imran is an experienced content writer who crafts engaging and informative articles for a variety of industries. With a keen eye for detail and a passion for storytelling, Imran delivers high-quality content that resonates with readers. Whether he’s writing blog posts, social media content, or website copy, Imran is committed to delivering compelling content that drives results.